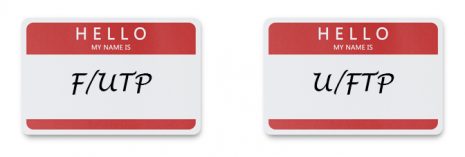

What’s in a name?

What does F/UTP or U/FTP mean? The letters are often banded about in the world of structured copper cabling, but what’s the difference?

F/UTP, stands for foiled, unshielded twisted pair. Each cable has an overall foil screen and the individual twisted pairs have none.

U/FTP, stands for unshielded foiled twisted pair. The main cable has no overall screening, however each internal pair of cables is twisted and wrapped with metal foil and a single drain wire.

What are the advantages of U/FTP over F/UTP?

Getting hot!

Selecting the cable design has a major impact on heat dissipation. Since U/FTP cables have a metal tape around each pair, while F/UTP cables has a single tape surrounding all 4 pairs, it means that heat generated inside each pair will be dissipated much faster and more efficiently with the U/FTP design.

Greater heat dissipation coupled with lower DC resistance provides for better Power over Ethernet or PoE support, and reduces the impact on transmission performance.

Long or short?

The Pair Lay Length (the twist rate of a pair) varies between F/UTP or U/FTP. In F/UTP cables the twisted pairs require a different lay length, ranging from long to short. This is to control crosstalk and interference between the pairs. In contrast U/FTP cables have similar long lay lengths, as the use of the foil shield on each pair helps to control crosstalk.

With the Longer Lay Length and no cross divider, the termination of U/FTP cables becomes simpler.

Termination

The F/UTP outer shield removal can be problematic as is the removal of any central cross filler element. While the construction/design of the U/FTP cable, despite having 4 shields to remove, allows these shields to be removed easily and quickly ready for termination. The U/FTP Longer Lay Length then offers a time saving as it requires less untwisting of pairs.

Flexible

Without the cross divide in a U/FTP cable, the diameter is usually smaller. Thinner cables are flexible and easier to route, which allows for improved cable tray fill rates, reduced conduit and cabinet congestion for better airflow and potential lower air conditioning costs.

More

Molex has a range of copper products on offer, click here to browse.

If you would like to read the article in full, please request access to the Molex Customer Support Portal.